10 Types of Beams In Construction

Types of Beams in Construction

The types of beams in constriction vary as essential horizontal structural elements that are quintessential in supporting the structures above them. They play a pivotal role in providing stability and strength to buildings and other infrastructures, through load distribution.

There are several types of beams in construction, each designed to carry specific types of loads and serve different purposes. Here are the most common types:

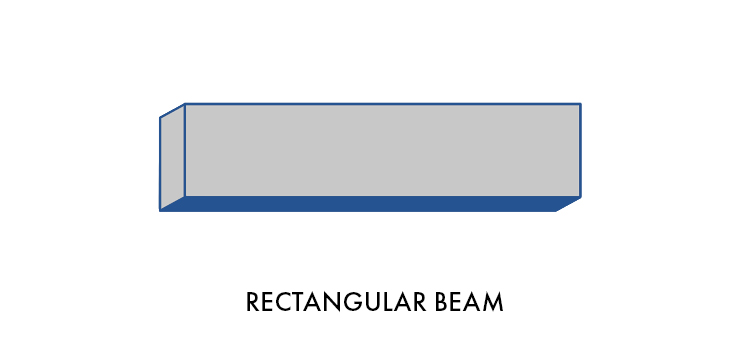

- Rectangular Beam: These are constructed with a rectangular cross-section and are stronger and stiffer as they distribute weight across four separate surfaces. Box beams are used in situations where heavy loads and long spans are a requirement.

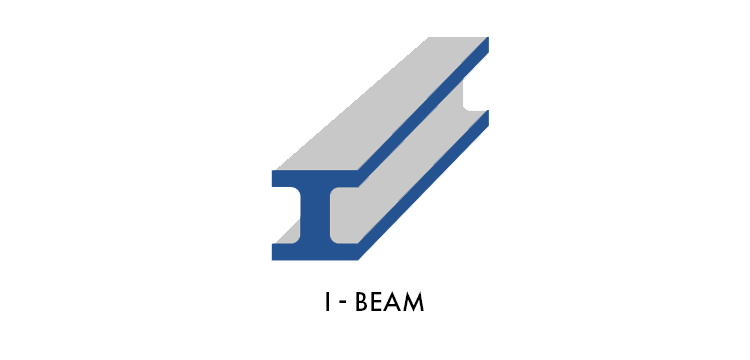

2. I-Beam: This bea, type has a cross-section that resembles the shape of the letter “I,” with two horizontal flanges connected by a vertical component. They are widely used in construction because of their excellent load-bearing capacity, making them ideal for large-scale construction projects.

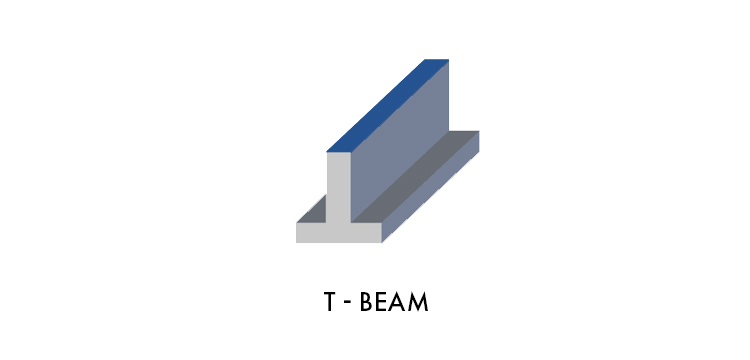

3. T-Beam: Resembling the letter “T” when viewed from the side, T-beams are used in floors and roofs to resist bending. They’re more efficient than rectangular beams when used in construction.

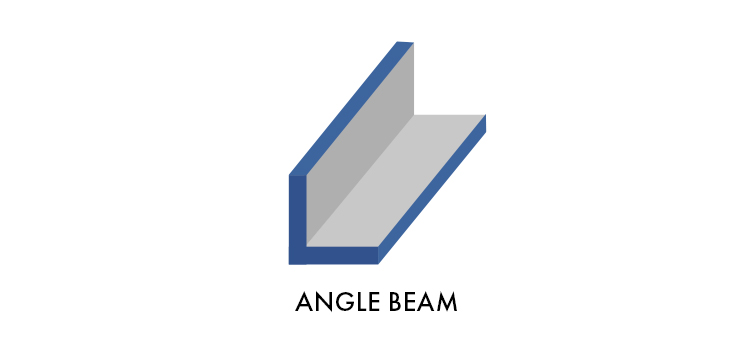

- Angle Beam: Angle beams, have an L-shaped cross-section and are often used for added strength and rigidity at corners. They are frequently used as braces or frames.

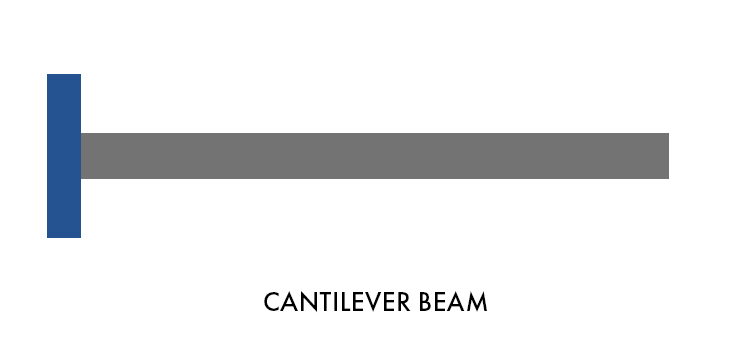

- Cantilever Beam: This beam type is fixed at one end and positioned horizontally at the other. These beams are commonly used in balconies, aircraft wings, and bridges.

- Fixed Beam: These beams are rigidly fixed at both ends and cannot move or rotate vertically. They are used when there is no or very minimal rotation at the supports.

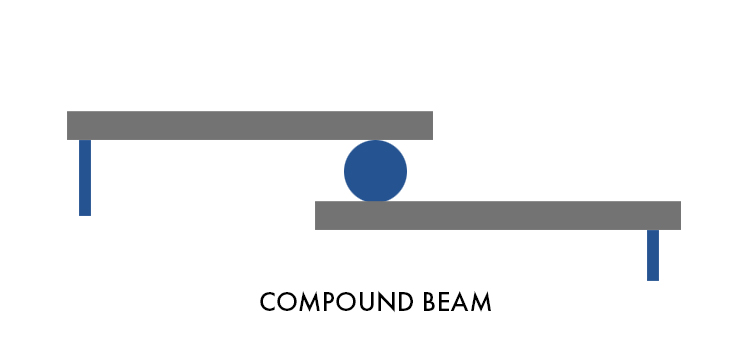

- Compound Beam: A beam made up of two simple beams connected by a third member known as a strut. Compound beams are used when a very long span is required.

Based on Material Used – Beams may be classified based on the materials used to construct them:

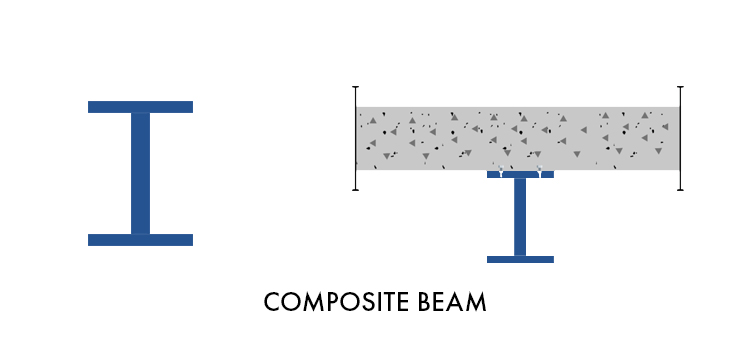

- Composite Beam: These construction beam types are constructed from two or more different materials, such as concrete and steel. The advantage of this type of beam is that it maximizes the benefits of the different materials to offer stability and resistance. Their application is useful in high-rise buildings, parking structures, industrial buildings, bridge construction, etc.

- Wooden Beams: These beams are made from wood, either the traditional way or by gluing together layers of timer creating a stronger and more versatile version.

- Reinforced Concrete Beams: These beams are reinforced with steel bars to enhance their tensile strength. Reinforced concrete beams are widely used in buildings, bridges, and infrastructure projects due to their durability and versatility. They provide excellent structural support and are capable of bearing heavy loads. These beams play a crucial role in distributing the weight of the structure and ensuring its stability and safety.

- Steel Beams: Steel beams are structural elements used in construction to support heavy loads over long spans. They are composed of steel plates welded together. Due to their high strength-to-weight ratio, they provide sturdy support while remaining relatively lightweight. Steel beams are commonly used in the construction of bridges, skyscrapers, and large buildings, providing structural integrity and stability. They play a crucial role in distributing the weight of the structure and ensuring its stability and safety.

Conclusion:

The types of construction beams are crucial in determining the overall strength and durability of a project. By carefully selecting the appropriate beam, engineers can ensure that structures stand tall and endure the test of time, guaranteeing safety and reliability for generations to come.